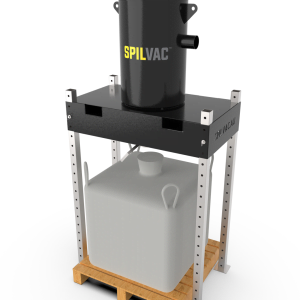

Spilvac Cubevac 800: Heavy Duty Vacuum Hopper

Introducing the CubeVac 800 – the latest addition to Spilvac’s range of heavy-duty vacuum systems. Designed and manufactured in Australia, this system is ideal for large-scale central vacuum tasks, from grain pit clean-ups to fly ash cleaning, offering a combination of power and flexibility.

Features and Benefits

- crane lifting lugs allow the system to be positioned for bridge work

- HEPA Exhaust filter available

- water separator and regulator

- large heavy-duty 4T hopper

- vacuum floor tool The Aspirator tool includes a 4inch tiger hose,20m as standard but can operate up to 40m

- Compressed Air Powered vacuum recovery system

- a full pneumatic system with reverse pulse filter cleaning and heavy-duty abrasive resistance manual butterfly valve

- Pallet sized footprint with fully height adjustable legs to handle Drums, Blast pots, Skips & bulker bags.

The CubeVac Recovery System series allows you to vacuum up all manner of waste or recycling material, the combination of High Air Flow and vacuum allows the system to clean up material from flour to steel shot.

It is designed to be used as a large-scale Central Vacuum System. The CubVac Recovery System can be placed outside a building and then piped inside not unlike a compressed air circuit, or it can be moved around your site to deal with any spills. The system is ideal for grain pits, fly ash cleans out, or general industrial house cleaning.

The system has been manufactured so that it has no electrical components which means that it is intrinsically safe in various environments. simply change the filter cartridge from time to time in order to maintain the full vacuum.

Our Australian-designed and manufactured Compressed Air Powered Cubevac Recovery System is new to the market. Using state the art venturi tubes and sonic air nozzles we are able to achieve very high vacuuming power and great airflow to lift all manner of products.

Vacuum clean-up becomes a breeze more brooms, shaver back aches from manual labor. Clean into the corners and under existing structures using our high-powered CubeVac Recovery system, saving you time and money.

CubeVac Recovery system is a 4-tonne hopper mounted onto a fully adjustable platform and a footprint that allows a standard forklift pallet to be positioned below our heavy-duty manual butterfly valve, its design allows product to be vacuumed into the hopper and then deposited into a blast pot, drum or bulker bag.

Get in touch

Call us to be connected to your nearest distributor or for any technical information you require.

the details relate to the model shown, however, we can configure the system to suit your available air desired performance, contact us to discuss this further.

Technical specification

input—-800CFM air input

output 1190CFM airflow

movement rate 8 to 10 tonnes per hour

What are the Most Common Questions About Large Vacuum Hoppers?

Large vacuum hoppers play an important role in industrial operations, especially those involving the handling of bulk materials and pneumatic conveying. Individuals exploring or utilising vacuum hoppers often have a series of inquiries before making a decision on a specific system. Others are aiming to enhance their understanding of its functionality. Here are the primary five queries frequently posed regarding large vacuum hoppers:

1. What is the hoppers storage capacity?

Potential users typically seek information on the volume capacity of the hopper to ensure it aligns with their requirements. The capacity directly influences how material the hopper can accommodate at once impacting the efficiency of production or processing lines.

2. How does the vacuum system operate?

Comprehending the workings of the vacuum system is important for users. This involves inquiries into how the hopper utilises vacuum power to transport materials and details about the type of vacuum pump used and including insights into transfer process efficiency.

3. Which materials can be handled by the hopper?

Users need clarity on which materials are compatible with the vacuum hopper. This may may include granules, powders, pellets or other forms in bulk. Factors like material characteristics—such as abrasiveness, bulk density and moisture content—play an important role in decision making.

4. What are the cleaning and maintenance procedures for the hopper?

When it comes to the use of vacuum hoppers in industries, potential buyers and operators often ask about how easy it is to clean and maintain the system. They inquire about access points for cleaning, how often maintenance is needed and if any special procedures or tools are required.

One common concern is the safety features of the hopper system. People frequently ask about features like overfill protection, pressure relief systems and any certifications or standards the hopper complies with, such as those related to explosion protection or food safety.

These inquiries help ensure that the large vacuum hopper meets needs covering aspects like handling, safety measures, maintenance requirements and capacity.

Where are Large Vacuum Hoppers Used

Heavy duty vacuum hoppers is equipment commonly used in a range of industrial settings to handle waste and, by-products effectively. Their design and strong suction power make them perfect for managing large quantities of materials. Here are five applications of heavy duty vacuum hoppers along with the industries that benefit from their use:

Cleaning Grain Pits: In agriculture in grain processing plants heavy duty vacuum hoppers play a role in clearing out grain pits. These pits can gather debris, dust and spilled grains that must be removed to uphold cleanliness standards and prevent contamination. The robust suction capability of these hoppers efficiently cleans the pits ensuring that grain handling areas stay tidy and secure while minimising the risks of pest infestations and grain spoilage.

Clearing Fly Ash: Within the energy production sector in coal fired power plants managing fly ash—a residue, from coal combustion—is essential. Heavy duty vacuum hoppers are employed to clear fly ash efficiently promoting plant cleanliness reducing air pollution levels and adhering to regulations. By collecting fly ash for disposal or recycling purposes, these vacuum hoppers contribute significantly to managing coal combustion by products.

Cement Industry Clean up: The cement industry produces types of waste such, as cement dust and spilled raw materials. To clean up these materials effectively from production floors and machinery vacuum hoppers are commonly used. This cleanup process is essential for keeping equipment running smoothly reducing product waste and ensuring worker safety by lesson risks.

Chemical Spill Cleanups: Chemical spills can pose a threat in the chemical manufacturing sector. Heavy duty vacuum hoppers play a role in efficiently cleaning up chemical spills, including powders and granules. They help prevent exposure, maintain a clean working environment and ensure that spills are managed in compliance with environmental regulations.

Metal Industry Clenaup: In the metalworking industry, vacuum hoppers are employed to gather metal shavings, grindings and other debris from cutting, grinding and machining activities. Given that these materials can be sharp and dangerous, efficient cleanup is crucial for safety and effectiveness. The use of vacuum hoppers aids in recycling metal waste while keeping work areas tidy and free of hazards.

These applications of heavy duty vacuum hoppers across industries illustrate their significance in promoting cleanliness, efficiency, safety measures and adherence, to regulatory requirements.