We cater to all budget levels, ensuring our products meet and surpass international market demands.

Industrial Dust Extractor

Powerful Suction, Quality Design:

Spilvac industrial vacuums are perfect as an Industrial Dust Extractor and stand out with their six times stronger suction compared to regular vacuums. They are perfect for industrial use, built to work in both dry and wet industrial vacuum conditions. Our range includes standard models and customised options to fit your specific needs.

Innovative and Diverse Range:

Innovation is key at Spilvac. We have a wide range of vacuums, including Blast Cabinet Vacuums for workshop cleaning, and Garnet Clean-Up Vacuums for medium blasting booths. Our team of engineers and designers always work to bring you the best products. a

Eco-Friendly and Energy Saving:

Our Industrial Dust Extractors use less energy but still deliver top performance. This means you can save on energy costs and help the environment. We focus on local supply chains to reduce our carbon footprint, making our products more sustainable than imported vacuums.

Flexible Supply Capacity:

Whether you’re a big company or an individual customer, we can supply any amount of vacuums you need. Our manufacturing arm, CP Metal Fabrication, helps us meet your demands quickly and efficiently.

Wide Applications:

Spilvac Dust control solutions are great for different industrial settings. They can handle anything from cleaning floors in workshops to dealing with waste in large blasting operations. They are user-friendly, making your cleaning tasks easier and more efficient.

With Spilvac, you get powerful, innovative, and eco-friendly industrial dust extractor vacuums that can handle a wide range of industrial cleaning needs.

Spilvac's High-Efficiency Vacuums

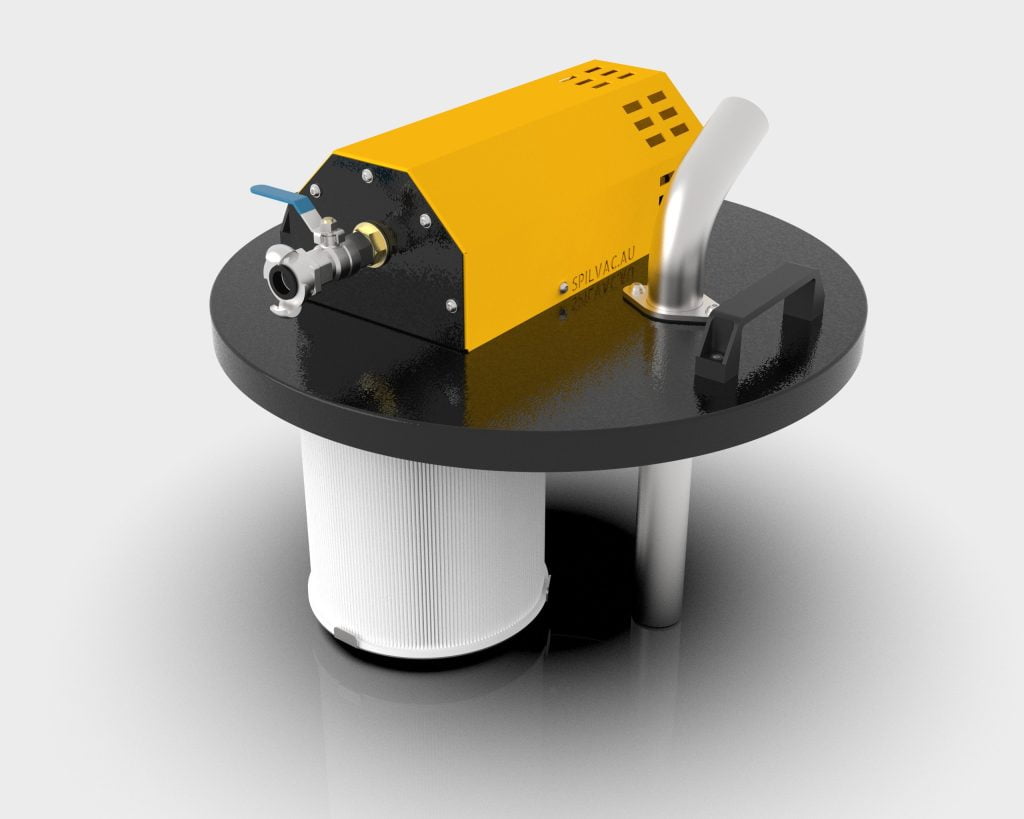

Blast Cabinet Vacuum – Dust Collector

The SV-60-D-38-RTG and SV-60-D-50-RTG Blast Cabinet Vacuum models include a special lid, a strong 200-litre drum, and a dolly for easy moving. They have a 4-meter hose, tools for floors, and a 2.5-meter grounding wire. These vacuums work at 55cfm with 80psi and can be hooked to a Nitto coupler and a 10mm airline. They are three times stronger than regular electric vacuums and are built to last long. They are great for cleaning blast cabinets and floors around them.

Light Workshop Floor Cleaning Vacuum – Dust Collector

The SV-100-D-38-RTG and SV-100-D-50-RTG Vacuum Kits are perfect for industrial floor cleaning, effectively handling everything from light metal dust to Garnet. These maintenance-free systems, with no moving parts, guarantee a long-term solution. They come equipped with a high-capacity 200-litre drum, a drum dolly, anti-static hoses in two sizes, a floor tool, a vacuum wand, an earthing wire, a standard filter cartridge, and drum reinforcing rings, requiring just 80 cfm at 80 psi of air.

Small To Medium Blasting Booths Garnet Clean-Up Vacuum – Dust Collector

The Twin Powered Venturi Head is equipped with advanced Sonic Air Nozzles and Venturi Vacuum Tubes, featuring internal baffles for noise reduction. This ready-to-use set includes a Drum-Lid assembly, a 200-liter steel drum with epoxy lining, a drum dolly, and is meant for dry uses. It comes with a choice of 4-meter anti-static vacuum hose (38mm or 50mm), a vacuum wand set, floor tool, a 2.5-meter earthing wire with grounding clip, a dry filter cartridge, and drum reinforcing rings. The models SV-120-D-38-RTG or SV-120-D-50-RTG operate at 100 cfm and 80psi, offering either a high airflow option (288cfm, 9.8inHg vacuum) or a high vacuum performance option (165cfm, 15.5inHg vacuum).

Medium To Large Blast Booths Garnet Clean-Up Vacuum – Dust Collector

Introducing the premier industrial vacuum solution for blasting booths: a versatile, air-powered system highly favored by distributors. Choose from four distinct models, including the “Ready to Go” kit or the innovative Drum-Lid version for your steel drum. The “Ready to Go” kit features two options: “SV-200-D-38-RTG” and “SV-200-D-50-RTG”. Each model is equipped with a 200-liter epoxy-lined steel drum, a drum dolly, and a 2.5-meter self-storing earthing wire with grounding clip. Depending on your needs, select from a 38mm or 50mm anti-static vacuum hose, along with a corresponding rod set and floor tool. This high-end model allows customisation with dual sonic air nozzles and advanced venturi tubes, ideal for either garnet or steel shot cleanup. Efficient in its operation, it requires just 160cfm at 80psi and offers a high airflow of 250cfm at 14.4inHg or a high vacuum airflow of 140cfm at 18inHg. This performance significantly surpasses that of traditional electric vacuums.

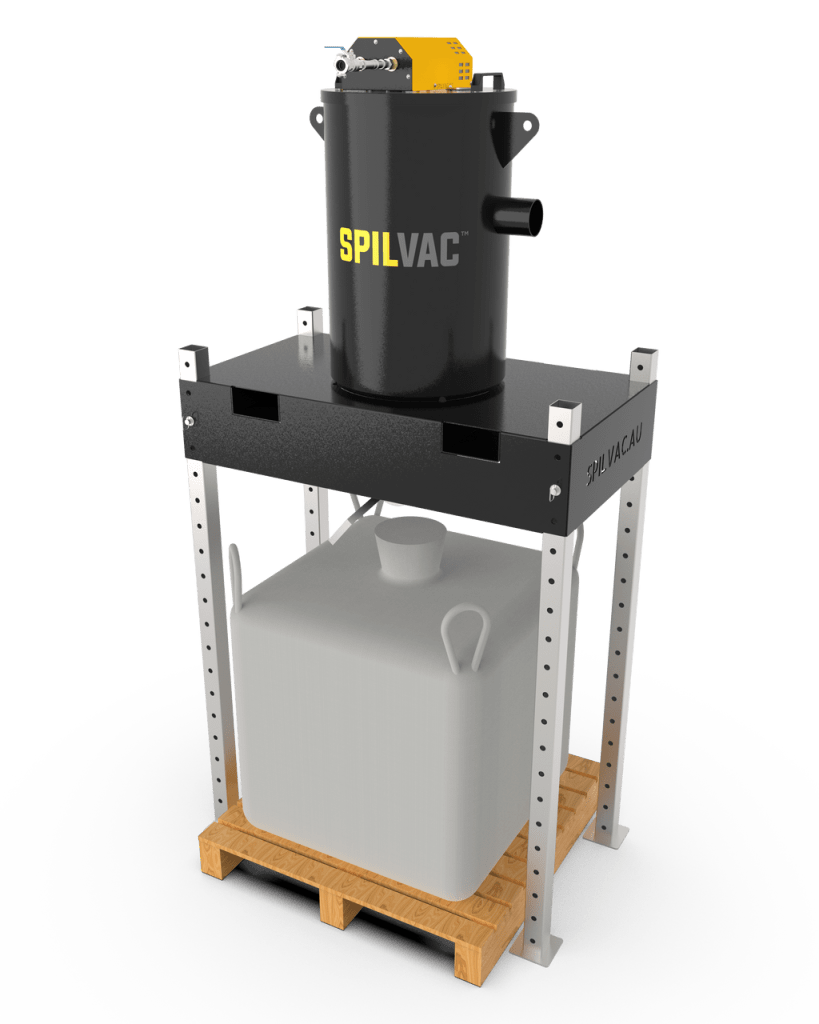

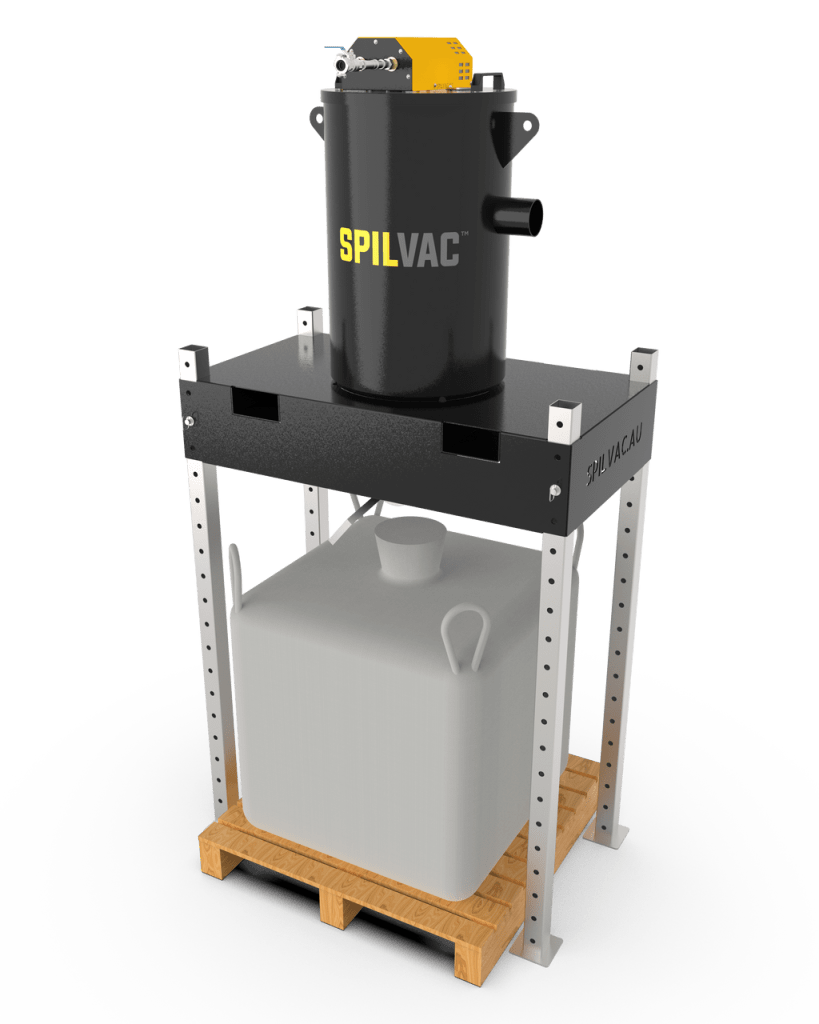

Blast Pot & Bulker Bag Loading Vacuum – Dust Collector

The Spilvac Elevator 200 is an innovative pneumatic elevator system that efficiently sucks up Garnet abrasive into a 200-liter container. It’s an upgrade for those using our Drum-Lid or Ready to Go models, with options including a Vacuum Generator. Its adjustable legs let you place various-sized Blast Pots, waste drums, or Bulker Bags underneath. This model features various air jets and Venturi tubes, offering eight power settings. It includes durable stainless steel tools for harsh abrasive environments, a single dry filter cartridge, and a choice of manual or pneumatic dump valves. Designed for small to medium businesses, it’s an efficient solution for blast rooms or shipping containers, crafted in Brisbane.

Blast Pot Loading With Dust Separation Vacuum – Dust Collector

The Spilvac Elevator 200 Series is an industrial vacuum system designed for versatility and efficiency. It features crane lifting lugs for easy movement, particularly useful in bridge construction. The unit has an adjustable base with built-in forklift slots and is compact enough to fit on a standard pallet. Its vacuum system is powered by 160 CFM of compressed air, creating up to 18 inHg vacuum with a large 63mm inlet for maximum airflow. It includes a high-quality European abrasive butterfly valve, with a pneumatic option for specific needs. This vacuum is ideal for a range of materials, from fine powders to heavy steel shots, and is perfect for various cleaning tasks like grain pit maintenance and fly ash removal. The Elevator 200 is an Australian innovation, featuring advanced Venturi Tubes & Sonic Air Nozzles for effective vacuuming and airflow. Its design is maintenance-friendly, requiring only occasional filter changes. The system also boasts a 200-litre hopper for easy waste transfer, enhancing cleaning efficiency and reducing labor.

Medium Vacuum Hopper – Cubevac Mini 200 – Dust Collector

The Cubevac Mini 200, expertly crafted in Australia by Spilvac, epitomises waste management innovation. This compact, cube-shaped vacuum hopper has a generous 200-liter capacity, catering to various industrial applications. Its robust vacuum power, reaching 18 inches HG (61Kpa), is complemented by a high-quality, European manual butterfly valve, with alternative pneumatic options available. The unit is mobile with either a 4-wheel design or elevator legs, and incorporates forklift compatibility for easy transportation. It comes equipped with a 20-meter anti-static hose, vacuum wand, and head set, and offers a choice of filters including disposable paper or washable polyester. This vacuum is exceptionally versatile, suitable for handling materials like steel shot and garnet, and is ideal for diverse environments ranging from factories to power stations and refineries, making it a valuable asset for efficient waste managements.

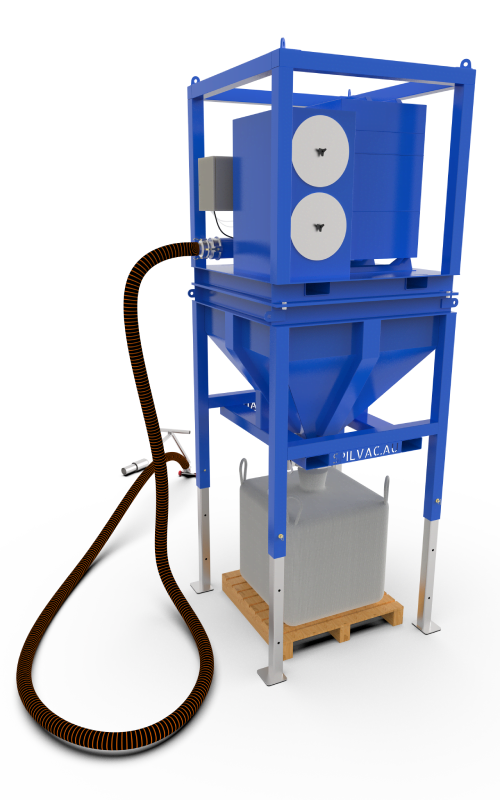

Heavy Duty Vacuum Hopper – Cubevac 800 – Dust Collector

Discover the CubeVac 800, a robust vacuum system from Spilvac, perfect for large-scale vacuum tasks like cleaning grain pits or managing fly ash. This Australian-made powerhouse combines strength with adaptability. It features crane lifting lugs for easy positioning, an optional HEPA Exhaust filter, a water separator and regulator, and a substantial 4T hopper. The Aspirator tool comes with a versatile 4-inch tiger hose, reaching up to 40 meters. Its compressed air-powered design includes a full pneumatic system, reverse pulse filter cleaning, and a tough manual butterfly valve. Designed for versatility, it fits pallet-sized spaces and adjusts for various containers. With high airflow, it efficiently handles diverse materials, from flour to steel shot. This electric-free model ensures safety in various settings. It’s a time-saving solution for industrial cleaning, easily handling up to 10 tonnes per hour. Contact us for customisation options based on your needs.

Why should you buy Spilvac Vacuums?

As industrial vacuum specialists, and in particular, industrial dust extractor specialists, we prioritise customer service and satisfaction. Our team, comprised of skilled designers, engineers, and tradespeople, is committed to delivering top-notch advice and insights. To demonstrate the effectiveness of our systems in action, we offer personalised video demonstrations and detailed technical data, showcasing how our products handle your specific needs.

Understanding and addressing our customers’ concerns is a key focus for us. We value each customer equally, regardless of the size or frequency of their orders.

At Spilvac, we stand out by using only genuine parts in our products, ensuring they are safe and reliable for industrial use. This is a significant advantage over the standard ordering systems of other suppliers. Our in-house manufacturing department incorporates advanced technology, including 3D printing, to craft our industrial vacuums.

We also offer a 12-month warranty on our industrial vacuum systems. Our commitment to continuous improvement is driven by the feedback and suggestions we receive from our customers. Our dedicated team is always encouraging public input to enhance our services further.

Occupational Health and Safety

At Spilvac, customer health and safety is our top priority. Our industrial vacuums feature unique designs with antistatic hoses and grounding clamps, providing maximum safety for users. This design prevents static accumulation in the drums, ensuring a safe operation. We take great pride in offering Heavy Duty Industrial vacuums that guarantee our clients’ safety and satisfaction. Our commitment at Spilvac is to deliver safe, reliable drum top vacuums to our customers.

Key Benefits for Spilvac Clients

At Spilvac, we prioritise creating safe designs that also aim to keep costs and energy use low. Our vacuums are notably more energy-efficient than conventional models. Our quick and flexible approach in developing and delivering solutions distinguishes us in the market.

Spilvac designs prioritise safety, cost-efficiency, and low energy use..

Our approach is fast and adaptable in providing customer solutions.

Clients receive a manufacturer’s warranty for peace of mind.

Standard product range meets most needs, with custom options available..

Spilvac serves a diverse clientele, from small businesses to major corporations, across various industry sectors.

Business Mission

Our goal is to become the top brand in advanced industrial vacuum technology. We strive to provide affordable, energy-saving, and secure dust collector systems for efficient handling and cleanup of both wet and dry materials.

Australian Made Industrial Dust Extractor Systems

Industrial dust extractor systems play a role, in enhancing air quality within mining settings. These specialised systems are designed to eliminate particles and debris from the air promoting an healthier work environment. By adhering to health and safety regulations industrial dust extractors help safeguard the well being of employees.

The operational principle of a dust extractor, also referred to as a dust extraction system focuses on capturing, filtering and releasing clean air into the surroundings. Initially, a robust suction mechanism draws in air into the system. Within the system filters are used to trap particles of varying sizes, including dust that poses risks to workers in close proximity. Following filtration the purified air is re-introduced indoors. The debris is either expelled outside based on specific system requirements and facility needs or captured ina purpose built hopper.

Modern dust extractor systems employ filtration technologies like HEPA filters of capturing minuscule particles with exceptional efficiency. Typically equipped with a collection unit for storing dust until proper disposal can be carried out these systems mitigate the possibility of recontamination within the workspace.

Spilvac Industrial Dust Extractors

Spilvac is a provider of industrial dust extraction systems offering a range of dust extraction products tailored to suit various industrial and mining settings. Our systems are designed with versatility and efficiency, in mind to meet the needs of any environment.

Wide Range for Different Dust Extraction Uses

Spilvac provides a range of industrial dust extraction systems for facilities of all sizes and industries. Whether dealing with particulate matter in precision manufacturing or larger debris in industrial settings Spilvac has the right solution. They offer units for smaller spaces and high capacity systems for larger industrial applications giving flexible options to effectively manage dust.

Cutting Edge Dust Filtration Technology

Spilvacs systems come equipped with filtration technology that ensures even the tiniest dust particles are captured. This feature is especially vital in industries where air quality directly impacts both product quality and worker health. The innovative filters also help extend the machines lifespan by preventing clogs and maintaining operation thus reducing maintenance costs and downtime.

Strength and Dependability

Designed to endure the demanding conditions of mining environments Spilvacs dust extractors are crafted from top quality materials.

Spilvacs dedication to quality and durability guarantees that their dust extraction systems can withstand heavy dust loads and function reliably for extended periods. This reliability makes Spilvacs dust extractors a wise investment for businesses offering lasting performance and cost effectiveness.

When it comes to compliance and safety Spilvacs industrial dust extraction systems are designed and manufactured to meet the relevant safety and regulatory standards. By following these requirements these systems assist facilities in avoiding penalties and reducing the chances of incidents associated with air quality. Spilvacs emphasis on compliance not only aids in meeting government regulations but also promotes a culture of safety in the workplace.

Spilvacs industrial dust extractors are an superb option for mining environments seeking dependable, effective and compliant solutions, for managing dust. With their range of systems, cutting edge filtration technologies and sturdy construction Spilvac ensures that industries can uphold a safe and compliant work environment.

Different Types of Dust Handled by Industrial Dust Extraction Systems

Industrial dust extraction systems are tools that can handle a variety of particles, in different industries. These systems are essential for maintaining air quality in workplaces by removing everything from powders to larger debris. In woodworking and carpentry they effectively eliminate wood dust, which poses health risks and fire hazards due to its flammability. The metalworking and fabrication sectors benefit from these systems as they manage metal filings and grindings which can be sharp, heavy and hot. Inhaling these metallic particles can pose health risks and damage machinery if not properly controlled.

Apart from wood and metal dust industrial dust extractors are also proficient at dealing with plastic and composite dust commonly found in industries like injection moulding and cutting materials. The chemical industry often encounters chemical powders that could lead to air quality levels and potential chemical reactions without proper dust extraction. Pharmaceutical facilities prioritise hygiene by using these systems to prevent contamination from ingredients and other fine particles.

In agriculture industrial dust extraction systems are used to handle dust such, as grains and crop particles.

Organic materials can present a risk of explosions in harsh conditions and can also impact respiratory health. In addition, the construction industry depends on dust extraction systems to handle silica dust, a substance produced during cutting and sanding tasks on materials like concrete and stone which can be harmful if inhaled.

Maintenance of Industrial Dust Extractors

It is crucial to maintain industrial dust extractors to ensure they function effectively and uphold working environments. A key aspect of maintenance involves inspection and cleaning of the filters. Filters collect dust, and particles becoming clogged over time and reduce efficiency and airflow. Cleaning the filters as per the manufacturers instructions helps sustain peak performance preventing strain on the system that could lead to issues.

Another important maintenance task is checking the ductwork and hoods for blockages. Wear signs. Dust buildup in ducts may occur over time if initial filtering fails to capture all particles. Keeping these pathways clear is essential for maintaining airflow and suction levels throughout the system. Periodic inspections are also necessary for fans and motors powering the extractors as these components may require adjustments or replacements, due to wear from use to ensure operation.

Regularly emptying and cleaning the dust collection units is crucial for maintenance. It helps prevent dust from circulating into the air and lowers the risk of fires or explosions with combustible types of dust. Additionally it’s important to check for any leaks or cracks in the system and fix them promptly to prevent air from escaping into the workspace. This ensures that the dust control measures remain effective.

Following a strict maintenance schedule recommended by the manufacturer of the dust extractor extends the equipments lifespan. It also keeps it running efficiently. Being proactive about maintenance can help avoid downtime and expensive repairs providing protection against dangerous dust and particles in industrial environments.