SPILVAC HOPPER STYLE BLAST POT & BULKER BAG LOADING – VACUUM RECOVERY & CLEAN-UP GARNET & STEEL SHOT:

Spilvac Elevator 200: Your Abrasive Solution

Overview:

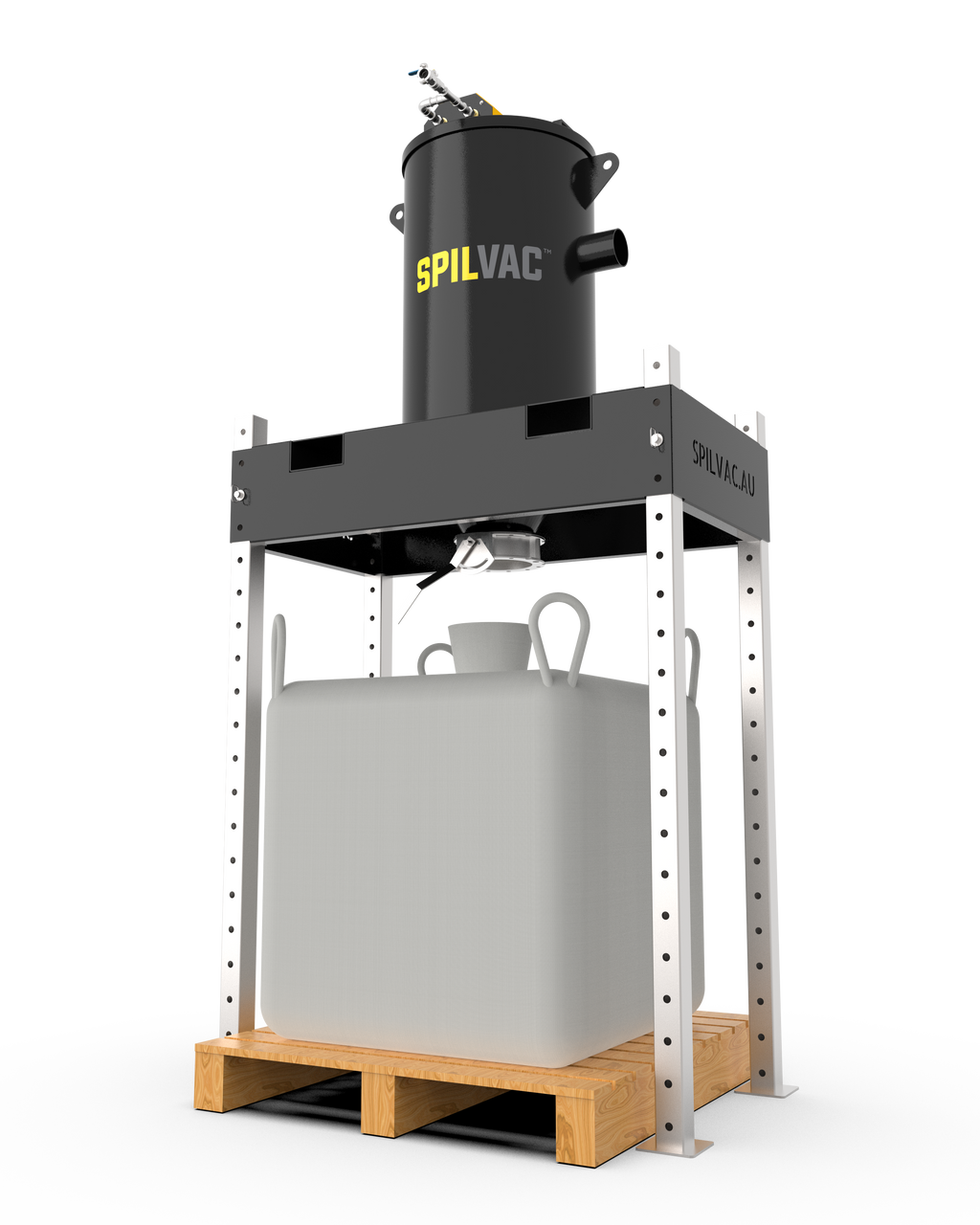

- The Spilvac Elevator 200 blast pot and bulker bag loading vacuum is a state-of-the-art, fully pneumatic system developed to efficiently handle abrasive materials like Garnet.

- It boasts a 200-litre hopper capacity, ensuring an ample space to store the vacuumed material.

- Proudly designed and constructed in Brisbane, this tool is an ideal investment for small to medium-sized businesses.

Key Features:

- Efficient Vacuum System: Swiftly vacuums Garnet abrasive from the floor into the hopper.

- Versatile Upgrade: Perfect for clients with our Drum-Lid Model or Ready to Go Model. Available as a standalone or a comprehensive system.

- Adjustable Leg Design: Accommodates Blast Pots of all sizes. Can also be positioned above a waste drum or Bulker Bag.

- Compact Footprint: Forklift-friendly design ensures easy mobility and transport.

- Power Variations: Can be customized with various Air Jets & Venturi Tubes, allowing up to 8 power variations.

- Durable Tools: Comes with Bulk Aspirator Pick-up tools and Stainless Steel Floor tools (both 50 & 63mm). These are designed for intensive abrasive use.

- High-Quality Filter: Features a Single Dry application Filter Cartridge. Options for washable Polyester or HEPA Filter cartridges are available for added purchase.

- Dump Valve Options: Standard is a Manual Butterfly European Abrasive Quality Valve. Upgrades to Pneumatic Operated or Rotary Valve styles are available.

- Space-Efficient Design: Its rectangular platform allows snug positioning against walls, making it perfect for shipping containers or blast rooms.

Additional Info: For more details, feel free to reach out to us. We’re here to assist you in making the best decision for your business!

The Spilvac Elevator 200: An Advanced Solution for Blast Pot Cleaning and Material Loading

Keeping blast rooms and blast pots clean is essential for safety and productivity. The Spilvac Elevator 200 is a quality system tailored to meet these stringent requirements. Whether you need to collect Garnet abrasive from the floor or fill a blast pot or bulker bag, our versatile Spilvac vacuum system offers an efficient solution. Proudly designed and manufactured in Brisbane, the Spilvac Elevator 200 is an investment for small to medium sized businesses.

What can the Spilvac Elevator 200 Cleanup?

The Spilvac Elevator 200 is specially designed to handle materials like Garnet. With its 200 litre hopper it provides storage space for collected vacuum debris materials. Operating entirely on pneumatic power it can withstand heavy demands without the maintenance issues associated with mechanical components. This sturdy design makes it an excellent choice for businesses seeking a lasting solution for their abrasive recovery requirements.

Efficient Vacuum System for Loading Blast Pots and Bulker Bags

An important feature of the Spilvac Elevator 200 is its vacuum system. The Spilvac Elevator 200 efficiently cleans up Garnet abrasive, from the floor and stores it in a 200 litre hopper, which is essential for maintaining clean and safe work areas and ensuring that the abrasive materials are easily accessible for reuse in blast pots or disposal in bulker bags.

Various Upgrade Options for this Industrial Vacuum System

For customers who already have purchased our Drum Lid Model or Ready to Go Model, the Spilvac Elevator 200 offers versatile upgrade possibilities. It can come with or without the Vacuum Generator depending on your configuration. This adaptable feature lets you enhance your system without duplication providing a cost effective solution. Whether you require a ready to go setup or just the hopper and vacuum assembly, the Spilvac Elevator 200 can be customised to fit your specific requirements.

Adjustable Leg Design for Loading Blast Pots and Bulker Bags

The standout feature of the Spilvac Elevator 200 is its leg design. This design enables operators to position the hopper over blast pots of any size, waste drums or bulker bags. This flexibility ensures that the system can be utilised in a variety of settings increasing its usefulness across many applications. The adjustable legs also make it easy to integrate with existing equipment reducing downtime during setup.

Compact Design for Easy Portability of the Spilvac Elevator 200 Vacuum System

The Spilvac Elevator 200 is manufactured with a design that makes it easy to move around. It is compatible with forklifts ensuring ease of mobility and transport. This feature is especially useful for businesses that require the vacuum system to be relocated across work areas or sites. The ability to effortlessly shift the system adds practicality and efficiency to its functionality.

Flexible Power Options

Operators can tailor the power of the Spilvac Elevator 200 by selecting from Air Jets and Venturi Tubes offering up to eight power variations. This customisation enables users to tune the systems power according to the needs of different tasks. Whether a strong suction is needed for debris or a gentle vacuum, depending on the materials this vacuum can be adjusted to deliver optimal performance.

Robust Tools Built for Heavy Duty Vacuum Usage

Equipped with Bulk Aspirator Pick up tools and Stainless Steel Floor tools in both 50mm and 63mm sizes this system is designed to withstand many applications. These tools are engineered to withstand wear and tear ensuring they can handle repeated heavy usage without compromising performance quality. Their durability guarantees lasting reliability reducing the frequency of replacements.

Premium Vacuum Filter Choices

As a feature, the Spilvac Elevator 200 includes a Single Dry Application Filter Cartridge known for its quality.

For flexibility you can choose between Polyester or HEPA Filter cartridges as optional extras. These superior quality filters guarantee dust and fine particle capture by the vacuum system ensuring an safe work environment.

Options for Dump Valves in Blast Pot and Bulker Bag Loading

The standard dump valve featured on the Spilvac Elevator 200 is a Butterfly European Abrasive Quality Valve. For added convenience and automation you have the choice to upgrade to a Pneumatic Operated or Rotary Valve style. These alternatives offer flexibility in how you operate the system allowing you to select the setup that best suits your workflow and operational requirements.

Efficient Use of Space

Thanks to its platform design the Spilvac Elevator 200 can be snugly positioned against walls making it perfect for use in shipping containers or blast rooms. This space saving design ensures that the vacuum system can be installed in confined spaces without compromising its performance. Placing the system against a wall also helps optimise workspace layout facilitating management of equipment and operations.

Manufactured in Brisbane – Quality and Dependability

Crafted with pride in Brisbane, the Spilvac Elevator 200 offers value for small to medium sized businesses. Its local design and construction guarantee that the system adheres to the highest standards of quality and reliability. When you invest in the Spilvac Elevator 200 you’re not just supporting Australian manufacturing. You’re also getting a product thats built to withstand the test of time.

In summary the Spilvac Elevator 200 is a cutting edge and versatile solution for blast pot and bulker bag loading as vacuum recovery. Its pneumatic operation, Australian build and wide array of features make it an excellent option for businesses aiming to streamline their recovery and cleaning processes. With numerous power options, durable accessories and quality filter choices the Spilvac Elevator 200 is tailored to meet the needs of duty industrial applications.

Why Choose the Spilvac Elevator 200 Blast Pot and Bulker Bag Loading Vacuum?

Efficient Vacuum System: Easily vacuums Garnet abrasive from surfaces into the hopper.

Versatile Upgrades: Suitable for customers with existing Drum Lid or Ready to Go models.

Adjustable Leg Design: Fits blast pots of all sizes and can be placed above waste drums or bulker bags.

Compact Design: Forklift friendly layout ensures easy maneuverability.

Customisable Power Options: Offers eight power variations, with Air Jets and Venturi Tubes.

Sturdy Tools: Comes with Bulk Aspirator Pick up tools and Stainless Steel Floor tools designed for heavy use. Explore our range of premium filter options. Choose from a dry application filter cartridge, with the flexibility of washable polyester or HEPA filters.

Upgrade your dump valve with options ranging from the manual butterfly valve to pneumatic or rotary valve styles.

Our space efficient design features a platform that allows for a fit against walls.

Opting for the Spilvac Elevator 200 means selecting a superior quality Australian Made pneumatic vacuum system that’s performance, reliability and versatility ultimately improving the efficiency and cleanliness of your blasting operations. Contact us today for more information and to discover how the Spilvac Elevator 200 can positively impact your business. Our team is dedicated to helping you make the best decisions regarding your recovery and clean up requirements.