Spilvac Elevator 200 Series: Industrial Vacuum Solutions

Key Features:

Flexible Positioning:

- Crane lifting lugs for easy positioning, especially for bridge work.

- A fully adjustable mounting platform that includes inbuilt forklift tines.

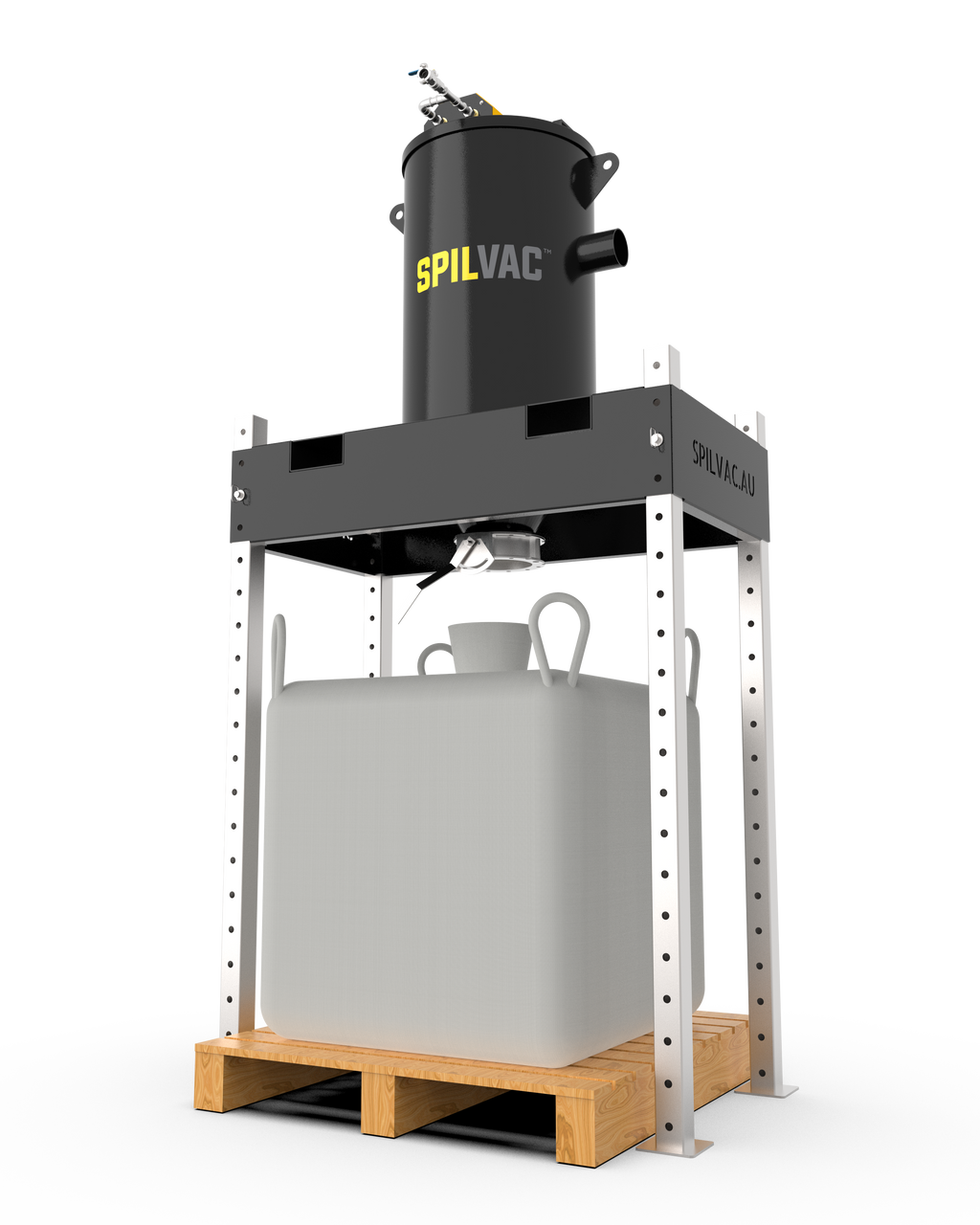

- Pallet-sized footprint, suitable for drums, blast pots, skips, and bulker bags.

High-Performance Vacuum System:

- Boasts a 160 CFM compressed air-powered vacuum generator.

- Produces up to 18 inHg of vacuum.

- A substantial 63mm section inlet ensuring maximum airflow.

Advanced Valve System:

- High-quality manual European-manufactured abrasive butterfly valve.

- Pneumatic valve option available for tailored applications.

Versatile Applications:

- Efficiently handles materials ranging from fine flour to robust steel shots.

- Optimally designed for grain pits, fly ash cleanup, and general industrial cleaning.

Design and Functionality:

The Spilvac Elevator 200 Series is uniquely crafted to function as a small central vacuum system. It offers the flexibility of placement, either outside a building with a piped circuit similar to compressed air systems or a movable setup for on-the-spot cleaning.

Thanks to its compressed air power, the system promises longevity with no moving mechanical parts that wear out. Maintenance is minimalistic, only necessitating occasional filter cartridge replacements.

Innovative Australian Design:

Proudly Australian-made, the Elevator 200 utilises cutting-edge Venturi Tubes & Sonic Air Nozzles. These innovations translate to impressive vacuuming power and robust airflow, catering to varied products and requirements.

Benefits:

- Effortless Cleaning: Say goodbye to manual brooms, shovels, and the physical strain of manual cleaning. The Elevator 200 Series reaches corners and under structures with ease.

- Cost and Time Efficiency: With the power of the Elevator 200, you save valuable time and money, streamlining cleaning processes and reducing manual labour.

- Intelligent Storage: The Spilvac Elevator 200 incorporates a 200-litre hopper. Mounted on an adjustable platform, it’s designed for easy product transfer. Vacuum products directly into the hopper, ready to be deposited into a blast pot, drum, or bulker bag.

The Spilvac Elevator 200 Series Blast Pot Loading with Dust Separation Vacuum is a high level solution for many vacuum needs tailored to meet the demands of modern industrial environments. With its cutting edge design, advanced features and reliable performance it serves as an essential tool for material handling and cleaning tasks. Here we will explore the standout features, advantages and applications of the Spilvac Elevator 200 Series underscoring its importance in the world of industrail pneumatic vacuum solutions.

Noteworthy Features of the Spilvac Elevator 200 Series Vacuum System

Distinguished by its array of features the Spilvac Elevator 200 Series stands out among other vacuum offerings. A key highlight is its positioning capabilities allowing adjustment to different industrial settings. The inclusion of crane lifting lugs facilitates exact positioning for tasks at elevated heights or bridge work enabling placement as required. Moreover the adjustable mounting platform comes equipped with built in forklift tines ensuring relocation and positioning is easy using a forklift. Its compact footprint similar to a pallet size footprint makes it compatible with containers such as drums, blast pots, skips and bulker bags. This design promotes effortless incorporation into manufacturing, industrial and mining environments to enhance operational efficiency and user convenience.

The Spilvac Elevator 200 Series features a superior quality Venturi vacuum system known for its suction power and efficiency. It utilises a 160 CFM compressed air powered vacuum generator to handle materials ranging from powders to coarse abrasives. With the ability to generate up to 18 inHg of vacuum it ensures material handling and cleanup tasks. The generous 63mm section inlet promotes airflow enabling the system to operate and manage large material volumes swiftly and easily. This high performance feature is essential for maintaining cleanliness and operational effectiveness in challenging settings.

An exceptional aspect of this system is its valve system offering control during the vacuuming process. Equipped with a European manufactured abrasive butterfly valve it guarantees reliable performance and accurate control when dealing with abrasive materials. For applications requiring control and automation there is an option for a valve that boosts the systems adaptability to specific operational requirements. This sophisticated valve mechanism plays a role in maximizing the efficiency and functionality of the Spilvac Elevator 200 Series.

The Versatility of the Spilvac Elevator 200 Series Makes it an Invaluable Asset Across Many Industrial Sectors.

The Spilvac Elevator 200 Series is known for its stellar design and strong vacuum capabilities allowing it to tackle a range of materials and tasks. For example, it efficiently sucks up grain in grain pits reducing the need for labour and enhancing efficiency. Its equipped to handle fly ash particles keeping work environments clean and safe. Besides these uses this system excels at industrial cleaning tasks where traditional methods may not suffice. Its versatility means it can adapt to individual needs making it a valuable asset in any industrial or farming/agricultural setting.

Design and Functionality of the Spilvac Elevator 200 Blast Pot Loading with Dust Separation Vacuum Makes it Ideal for Industrial Settings

The Spilvac Elevator 200 Series Blast Pot Loading with Dust Separation Vacuum is specifically tailored for heavy use offering flexibility, efficiency and easy maintenance. It can function as a vacuum system with several placement options including outside a building using a piped circuit similar to compressed air setups or as a mobile unit for quick spot cleaning. This versatility ensures that the system can be customised to suit your requirements. Powered by air and designed without moving parts that wear out easily the system boasts durability with minimal maintenance needs. Regular filter cartridge replacements are the upkeep required making it both efficient and cost effective. In designing the vacuum system the focus on durability and minimal upkeep is essential for ensuring the long term effectiveness of operations.

Innovative Design from Australia

The Spilvac Elevator 200 Series proudly designed and manufactured in Australia, incorporates cutting edge technologies and innovative design features. Utilising Venturi Tubes and Sonic Air Nozzles results in vacuuming capabilities and strong airflow catering to a variety of products and needs. The superb construction showcases the expertise and dedication to quality that characterise all our manufacturing. The smart build guarantee that the system can meet the standards expected in challenging industrial settings.

What are the Advantages of the Spilvac Elevator 200 Series

Opting for the Spilvac Elevator 200 Series Blast Pot Laoading with Dust Separation vacuum brings benefits that boost efficiency and decrease manual work. One key advantage is the systems ability to deliver effortless cleaning. The robust vacuum system eliminates the need for brooms and shovels reducing strain and enhancing productivity. It can easily access corners and tight spaces ensuring a high quality cleaning process. This user friendly feature is crucial for maintaining an effective workspace.

Another significant benefit is the cost effectiveness and time savings offered by the Spilvac Elevator 200 Series. By streamlining the cleaning process this system saves time and resources. The decreased reliance on labour along with the efficiency of the vacuum system result in cost savings. This efficiency plays a role in environments where time and resources are often limited.

The Spilvac Elevator 200 Series offers storage capabilities that add to its value. It features a 200 litre hopper mounted on a platform allowing for easy product transfer. Vacuumed items can be deposited directly into the hopper for transfer to blast pots, drums or bulker bags. This functionality streamlines material handling processes simplifying the management of material quantities.

The Ultimate Industrial Vacuum Solution

To sum up, the Spilvac Elevator 200 Series stands out as an excellent vacuum solution, for loading blast pots and bulker bags meeting the demanding requirements of cleaning and material handling tasks. The Spilvac Elevator 200 Series is a must have tool for any setting thanks to its incorporation of proven, exceptional quality vacuum technology, advanced valve choices and wide range of uses. Opting for this system means opting for effectiveness, longevity and user friendliness. Whether you’re dealing with particles, heavy debris, grain cleanup or anything in between, this vacuum system delivers the power and dependability needed to uphold an productive workspace. Discover the advantages of the Spilvac Elevator 200 Series. Take your cleaning and material handling procedures to new heights. This investment will unquestionably boost your capacities and enhance efficiency in cleaning your industrial setting.

Connect with Us:

Seeking more technical insights or keen to find a distributor near you? Don’t hesitate to call us.