We are unique because of our expertise in designing and developing vacuum generation systems. Every model within our industrial drum top vacuums range matches and exceeds the global market needs.

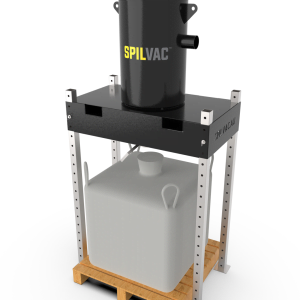

Drum Top Vacuum

-

Blast Cabinet Vacuum – Spilvac Vacuum

$0.00 -

Light Workshop Floor Cleaning Including Powder Coating – Spilvac Vacuum

$0.00 -

Small To Medium Blasting Booths Garnet Clean-Up – Spilvac Vacuum

$0.00 -

Medium To Large Blast Booths Garnet & Steel Shot Clean-Up – Spilvac Vacuum

$0.00 -

Blast Pot & Bulker Bag Loading – Vacuum Recovery & Clean-Up – Spilvac Hopper System

$0.00 -

Blast Pot Loading With Dust Separation Vacuum – Spilvac

-

Medium Vacuum Hopper – Cubevac Mini 200

-

Heavy Duty Vacuum Hopper – Cubevac 800

Pneumatic Drum Top Vacuum Feature

Efficiency

Spilvac products produce six times the suction capacity of conventional motor-driven products on the market. All our drum top vacuum products are of high-quality design.

We specialise in vacuums that suit both dry and wet conditions. Besides the standard Industrial vacuums, our engineering team can design products tailored to your specifications.

Continuous product innovation is part of our strategy. With a team of engineers and designers, our products are exceptional. We have many varieties like Blast Cabinet Vacuum, Light Workshop Floor Cleaning Spilvac Vacuum, Small To Medium Blasting Booths Garnet Clean-Up Vacuum, Medium To Large Blast Booths Garnet & Steel Shot Clean-Up Vacuum, Blast Pot & Bulker Bag Loading Vacuum, Blast Pot Loading With Dust Separation Vacuum, Medium Vacuum Hopper and Heavy Duty Vacuum Hopper.

Sustainability

Our industrial drum top vacuums have an energy reduction component. The products are designed for lower air consumption without compromising performance and quality. The supply chain for our products are based onshore thus minimising the carbon footprint unlike versions of imported vacuums.

Our products ensure that customers utilise less energy and therefore lower running costs and unnecessary waste of energy. Most vacuum systems rely on low-power motors to minimise energy usage. Unlike the Spilvac vacuums, energy conservation is our strategy and at the forefront of our design philosophy.

Supply Capacity

Spilvac is well equipped to supply any quantities based on demand. That includes bulk buyers, individual customers, and industrial orders. Because of our in-house manufacturing arm, CP Metal Fabrication, we can adjust our supply requirements to meet demand.

We don’t outsource engineering and designing.

Up to date with the latest solutions to match your requirements.

Spilvac has a team of in-house staff with the necessary experience to design, develop, test and finalise for manufacturing our products. That makes our high-quality industrial pneumatic drum top vacuums are superior in comparison to the rest of our competitors.

Why should you buy Spilvac Vacuums?

Our experts are always available to answer questions and deliver professional advice. We even go to the extent of providing video feedback on our systems on your product so you can see for yourself how our systems moving your product. We will provide video and technical data on movement rates.

We devote our time to understanding the concerns of our customers. Every customer is valuable regardless of the magnitude of orders or business volumes.

Our products are reliable and manufactured using genuine parts. Unlike the generic ordering system from other suppliers, Spilvac has a manufacturing department. Every product is safe for industrial levels of usage.

Spilvac has a 12-month warranty facility for industrial vacuum systems. We are constantly upgrading our service based on our customer feedback and suggestions. Our dedicated staff encourage the public to express their feedback for service improvement.

Our qualified designers, engineers and tradesmen use high-quality equipment for manufacture combined with 3D printing technology.

Occupational Health and Safety

Spilvac values the health and safety of our customers. Our designs are fitted with antistatic hoses. They also have grounding/earth clamps to ensure the operator’s safety.

This also ensures no static build-up within the drums. Our goal is to ensure the safety of our clients when they use our Heavy Duty Industrial vacuums. Spilvac takes pride in knowing that our customers are safe when using our drum top vacuums.

Key Benefits for Spilvac Clients

The design process is tailored towards safety, minimising costs and reducing energy consumption. Spilvac vacuums consume less power than traditional vacuums.

Our ability to be nimble and develop solutions, test and provide answers quickly for customers sets us apart.

Clients will enjoy a manufacturer warranty and peace of mind.

Our standard product range will cover 95% of our customers’ needs, but we have developed many bespoke/customised solutions for many years, so if you don’t see the exact solution you’re looking for don’t hesitate to get in touch.

Spilvac welcomes every customer.

Our customer base ranges from small-scale businesses to large-scale corporations.

Some of the key customers operate in the following industries

Business Mission

Our mission is to be the number 1 brand of state-of-the-art industrial vacuums. We aim to be the key supplier of cost-effective, energy-efficient, and safe industrial drum top vacuum products for the purpose of product recovery, movement and clean up of both wet and dry products.

Best Industrial Vacuum in Darwin: Spilvac’s Venturi Power for Tough Conditions

If you are looking for the best industrial vacuum Darwin you’ve found it. Darwin’s industrial environment is marked by extreme heat, high humidity, and heavy-duty cleaning demands. In these challenging conditions, businesses need reliable and robust equipment that can withstand the climate and handle tough cleaning tasks. Spilvac’s industrial vacuum systems, powered by multi-Venturi technology, offer an optimal solution for the unique needs of Darwin’s industries.

Meeting the Demands of Darwin’s Industrial Sector

In Darwin, industries such as mining, construction, and manufacturing often face harsh operating environments where dust, debris, and hazardous materials accumulate rapidly. Keeping these spaces clean isn’t just about aesthetics—it’s essential for safety, compliance with regulations, and maintaining productivity. Ordinary vacuums, especially those powered by electricity, are often insufficient in Darwin’s extreme conditions. The risk of overheating, electrical malfunctions, or inadequate suction can slow down operations, increase downtime, and even compromise worker safety.

Spilvac’s industrial vacuums, designed with multi-Venturi technology, offer a superior alternative. Unlike conventional electric vacuums, Spilvac’s systems use compressed air to generate powerful suction. This pneumatic system is highly effective at cleaning up large volumes of debris, fine dust, and even hazardous materials. For industries in Darwin that deal with volatile or combustible substances, Spilvac vacuums eliminate the risk of electrical sparking, making them a much safer option in explosive or flammable environments.

The Power of Spilvac’s Multi-Venturi Technology

At the heart of Spilvac’s vacuum systems is its multi-Venturi technology, which significantly amplifies airflow to create an exceptionally strong vacuum force. The Venturi effect is a principle that uses airflow to increase suction power without the need for complex electric motors. This design ensures maximum efficiency with minimal parts that could wear out or break down, making these vacuums both powerful and low-maintenance.

In industries where the vacuum system needs to run continuously in extreme conditions, such as under Darwin’s intense heat and humidity, Spilvac’s pneumatic vacuums stand out as the best solution. The lack of moving parts significantly reduces the risk of mechanical failure, keeping operations running smoothly without frequent repairs or downtime. The systems are engineered to handle the toughest conditions, making them ideal for Darwin’s climate, where high temperatures can overheat traditional electric vacuums.

Safety and Durability in Explosive Environments

One of the primary concerns in Darwin’s industrial environments is the handling of hazardous and combustible materials. Industries like mining and chemical manufacturing frequently work with substances that, when airborne as dust, can be highly explosive. Using electric vacuum cleaners in these environments poses serious safety risks due to the potential for sparks or electrical malfunctions.

Spilvac’s pneumatic vacuum systems address this issue directly. By using compressed air instead of electricity, these vacuums operate safely in areas where explosive materials are present, making them an essential tool for industries that prioritize safety. Additionally, the vacuum systems are built to withstand harsh environmental factors, ensuring long-term durability even in the most extreme settings. For businesses in Darwin, this means peace of mind knowing their vacuum systems can handle hazardous materials without risking worker safety or costly equipment damage.

Low-Maintenance and Long-Term Reliability

Another key advantage of Spilvac’s pneumatic vacuums is their minimal maintenance. The lack of electric motors or complex mechanical parts means there are fewer components that could wear out or require servicing. This translates to a lower risk of mechanical failure and reduced maintenance costs, which is particularly beneficial in Darwin’s remote locations where access to repair services can be limited.

For businesses operating in Darwin’s industrial sector, downtime due to equipment failure can be both expensive and disruptive. Spilvac’s reliable vacuum systems are designed to minimise this risk, offering long-term performance and durability even in the most demanding environments. With Spilvac, companies can focus on their core operations, confident that their cleaning equipment will continue to function effectively with minimal intervention.

The Best Choice for Darwin’s Industries

Spilvac’s multi-Venturi technology offers unmatched suction power, durability, and safety for Darwin’s challenging industrial conditions. Whether it’s cleaning up hazardous materials in mining or maintaining safe, debris-free environments on construction sites, Spilvac’s pneumatic vacuums are designed to deliver optimal performance. The system’s ability to handle extreme heat, humidity, and hazardous substances makes it the best choice for businesses in Darwin.

For industries looking for a reliable, powerful, and low-maintenance vacuum solution that can withstand Darwin’s tough conditions, Spilvac’s advanced technology stands out as the top option.